To see a video of how DMT’s sensors work, visit dmt-group.com/ rideguard.html

To learn more about Mobaro’s platform, visit mobaro.com

The era of predictive maintenance arrives

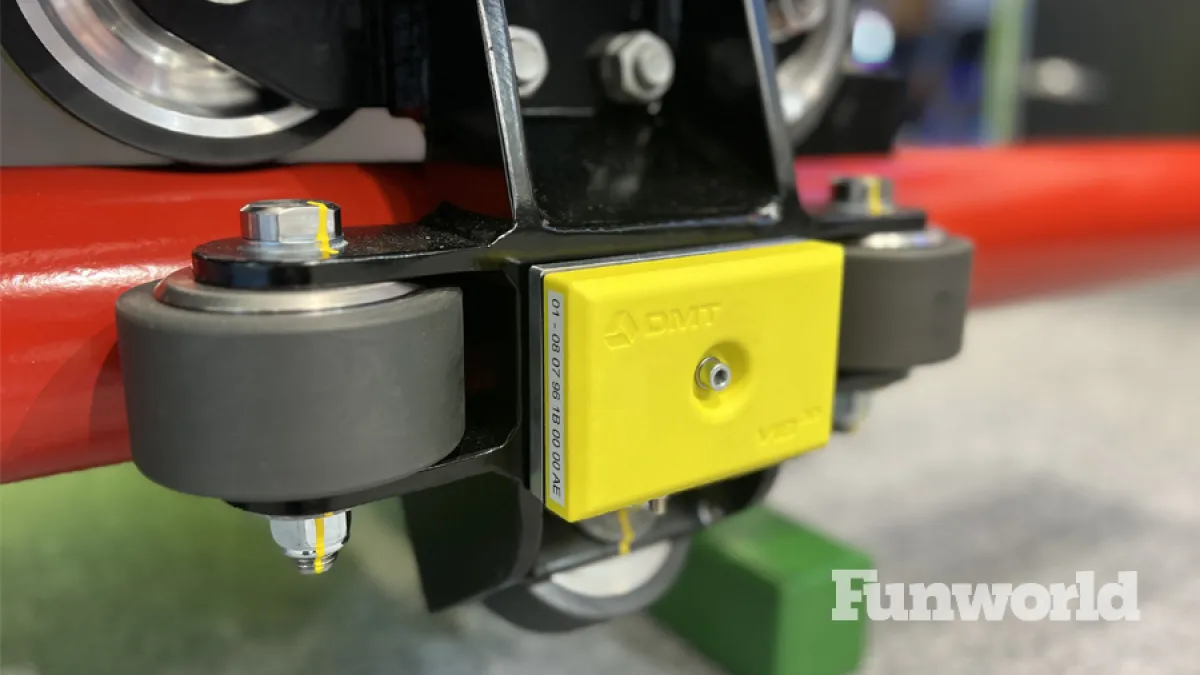

THE FUTURE WAS ON FULL DISPLAY this September at IAAPA Expo Europe 2025 in Barcelona. A keen eye could catch a glimpse of what’s called “predictive technology” in the Vekoma Rides booth. The Dutch manufacturer partnered with Karls Erlebnis-Dorf, a German theme park operator, to install new-age sensors on a pair of trains bound for two custom-designed family boomerang coasters the operator will open in summer 2026.

What do the sensors do? Allow an amusement park ride to talk—quite literally.

“We’re using technology to get information out of the ride; They are now talking to us,” says David Bromilow. “These smarter solutions are more efficient as we look at deploying updated maintenance solutions.”

Bromilow would know. He’s spent 40 years on the forefront of ride maintenance and enhancing ride safety systems at both consultancies and theme parks. Today, as a special advisor to Mobaro, Bromilow says the global attractions industry has entered a new era.

“I’ve seen the days when we used to have reactive maintenance: when it broke, we fixed it. Then we moved into preventative maintenance, and that was a great era to be in. But now, we’re moving forwards into predictive maintenance,” he explains to Funworld.

Here’s how the sensors from DMT, a TÜV NORD GROUP company, work: placed on different components—like a wheel bogie found on Karls Erlebnis-Dorf’s new family coaster— the DMT sensors send information back to a park’s maintenance department, alerting technicians when a problem may be developing.

“It would be really nice to know if the temperature of the hydraulic pump had risen by three degrees. It would be very useful to know if the hydraulic pressure has dipped. Or, if there’s a little vibration in a main gearbox,” Bromilow illustrates. “So, using sensors on the ride sends the maintenance shop a signal and creates a work order.”

The same sensors can also be placed on pumps and filters used at a water park and life support systems found at aquariums, along with older and existing rides found at parks.

“In years gone by, we’d send maintenance guys in the afternoons back to the rides to take temperature readings and to take pressure readings. But of course, today, we’re very conscious of ride enclosure areas,” Bromilow says of low zones and areas underneath a coaster’s chain drive.

The new reporting system works outside of a ride’s existing control system, providing another layer of support.

“They’re not interfering with the control system, which is very, very important. Parks and manufacturers like an airgap between technology and their computer system, rightfully so for security purposes.”

But, wait. There’s more. Like an infomercial on television, the sensors from DMT can provide more insight using machine learning. With an added AI component, DMT RideGuard’s system monitors the technical condition of rides in real time. It can then seamlessly be integrated into the Mobaro CMMS system currently in use at over 300 parks and attractions around the world. Thus, a computer can begin to predict when a mechanical failure could occur—and alert maintenance teams in the field to pay extra attention to an area of concern.

“The system now is now learning about these failures; the frequency of the failures; and then mean time between downtime— It’s so incredible,” Bromilow concludes with an excited grin.

To see a video of how DMT’s sensors work, visit dmt-group.com/ rideguard.html

To learn more about Mobaro’s platform, visit mobaro.com

Follow IAAPA for news and event announcements in your favorite social media apps

Connect with the Real Stories Behind the Fun

Follow our social media for authentic stories, special moments, and behind-the-scenes looks from the attractions world.